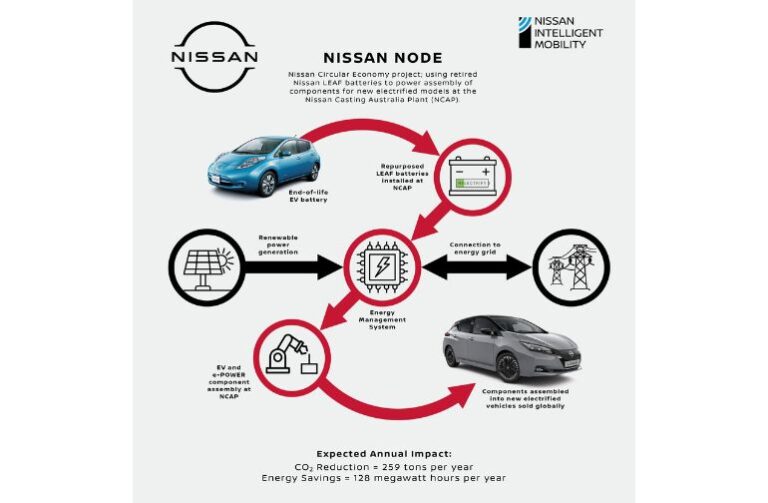

Nissan Australia is set to launch an innovative, industry-first Circular Economy project in Victoria, with the Nissan Casting Australia Plant (NCAP) to use recycled LEAF batteries to power part of its production facility.

In an exciting window into the future for end-of-life electric vehicle batteries — and an important step towards Nissan Australia’s goal of carbon neutrality — the NCAP Battery Project, called Nissan Node, will see a new solar array installed at Nissan Casting Australia, as well as new EV chargers.

In its most simplified form, the Nissan Node will include the installation of a new Battery Energy Storage System made of nine repurposed Gen 1 Nissan LEAF batteries at the Nissan Casting Australia Plant, which will be charged via the solar array.

It’s a true Circular Economy project, using end-of-life batteries from the Nissan LEAF – the world’s first mass-market electric vehicle – and renewable energy to power part of the production of components for Nissan’s global EV models, as well as help supply the new EV chargers to recharge staff vehicles.

The project is estimated to reduce Nissan Casting Australia’s annual C02 emissions by 259 tons, while saving 128 megawatts of energy every year.

“This isn’t just a hugely exciting project, but an important step into the future for end-of-life EV batteries,” says Nissan Casting Australia Managing Director, Peter Jones.

“As an early pioneer of the electric vehicle both globally and locally, we can also demonstrate leadership in second-life battery initiatives. I’m proud that this solution is every bit as innovative as the launch of the LEAF in Australia was more than 10 years ago.

“Already the Nissan LEAF comes with vehicle-to-grid technology from factory, which will allow Australian EV owners to use their vehicle to power their homes, and could be used to help stabilise the electricity grid, but commercial Circular Economy projects like this are a viable, sustainable and innovative solution for end-of-life EV batteries, too.”

The Nissan LEAF has just been updated for the 2023 model year, with a new look and leading-edge technology designed to broaden the popular electric vehicle’s appeal. Key style updates, including wheels-up design changes, and new safety features appear across the two-model range.

The continued global EV transition not only represents an exciting opportunity for drivers, but it continues to be an opportunity for local manufacturing.

Nissan’s NCAP operation has been a mainstay of the industry since its establishment in 1982. Today, in excess of 50 per cent of NCAP’s operation is dedicated to the manufacturing of high-quality aluminium castings that are fitted to Nissan’s battery electric and hybrid vehicles sold globally, with NCAP recognised as a centre of manufacturing excellence within the global Nissan network.

In fact, every Nissan LEAF EV sold globally has components fitted that were manufactured here in Australia.

“This is another great, innovative idea from the Nissan Casting Australia Plant (NCAP) team that creates a sustainable solution for Nissan’s end-of-life electric vehicle batteries,” says Mr Jones.

“This Nissan Node Project perfectly demonstrates the Nissan way of thinking to ‘Challenge for the Future’. We are very proud of our NCAP team, which continues to innovate and improve to ensure our advanced manufacturing capability, not only for Nissan but also for Australia.”

Similar projects are already underway around the world, including a trial with the East Japan Railway Company which uses second-life LEAF batteries to power railway crossings, and with the 4R Energy Corp in Japan, which is developing the technology and infrastructure to recycle, resell and reuse the batteries in Nissan EVs as a power storage solution.

The Node Project is being completed in partnership with innovative Melbourne-based company, Relectrify. Relectrify is the developer of ground-breaking battery management and inverter technology that dramatically extends the life of batteries, reduces battery system costs, and enables the repurposing of high-quality second-life batteries from electric vehicles.

Relectrify’s ReVolve Battery Energy Storage System being installed at the NCAP is a first-of-its kind product built from end-of-life LEAF batteries.

“We are delighted to be working with Nissan on this initiative, which positions Australian innovation at the forefront of the global transition towards both carbon neutrality and the Circular Economy,” says Relectrify CEO, Val Muenzel.

The Nissan Node will be completed this year, marking an important step on Nissan’s journey to carbon neutrality, and it will contribute to the company’s broader EV36Zero global vision.

EV36Zero is Nissan’s $1.7 billion Electric Vehicle Hub in Sunderland, UK, which will create a world-first EV manufacturing ecosystem that brings together electric vehicles, renewable energy and battery production, and that sets a blueprint for the future of the automotive industry.

That project includes the creation of a renewable energy micro-grid that will power EV and battery production at Nissan’s Sunderland manufacturing facility, saving up to 55,000 tonnes of carbon annually and establishing Nissan as the industry leader in zero-emission automotive manufacturing.