This is one of the big areas of debate when talking about the adoption of electric vehicles by fleets. The anti-EV crowd will tell you the batteries end up in landfill; forever poisoning the earth which makes them worse than ICE vehicles. The pro-EV crowd talks about recycling and a circular economy for the rare metals and other battery components.

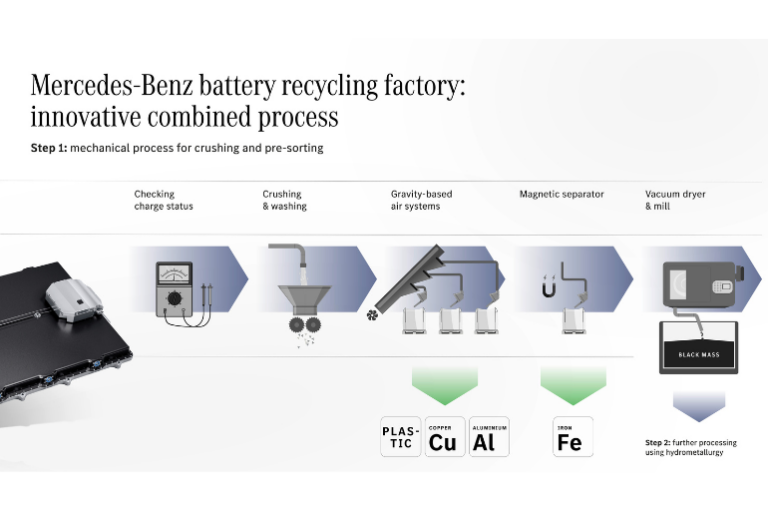

In October, Mercedes-Benz opened a battery recycling factory in Kuppenheim, and they have provided this simple explanation of the complicated process that combines mechanical and hydrometallurgical recycling processes at one location.

Hopefully this helps Fleet Managers understand the process and debunk one of the many myths that try to prove that EVs are bad for the world.

EV battery recycling – step by step

- After checking the state of charge, the process starts with placing the battery modules on a conveyor belt. The batteries are then mechanically crushed, washed and separated into coarse and fine fraction.

- Using gravity-based air systems, magnetic separators, a grinder and various sieves, plastics, copper, aluminium and iron are separated and packaged according to type. At the same time, the black mass contained in the dried coarse material is separated.

- The previously separated fine fraction contains the largest proportion of black mass. This is filtered and further processed together with the mass from the coarse material in the hydrometallurgy. Here, the metals are first dissolved into a liquid solution by leaching. The undissolved graphite is separated using filters and then packaged. The precipitated iron and the aluminium components are treated in the same way.

- The valuable raw materials such as copper, cobalt, manganese, nickel and lithium are recovered one after the other, in a multi-stage chemical separation process. Cobalt and nickel are then crystallised.

The battery recycling factory has an annual capacity of 2,500 tonnes. The recovered materials are fed back into the material cycle and are used in the production of more than 50,000 battery modules for new all-electric Mercedes-Benz models. This closes the raw-material-loop.