There is so much time being spent on the issue of how to charge fleets once they transition to electric cars. EV Transition Plans are being written by Fleet Managers, Sustainability Managers and Consultants with sections on charging infrastructure without a clear road forward.

During January I visited the offices of EVSE in Sydney to learn more about the fast changing world of EV charging infrastructure and the software developments that are allowing load management to become the solution where buildings have limited electricity supply with increasing demand from fleets.

It turns out that majority of organisations planning to use onsite charging could build a charging solution without investing in an electrical network upgrade and save thousands of dollars.

How? Load management is the answer. Not managing the GVM and GCM of the vehicles. Managing the electricity loads in the depot or building where the EV charging stations will be located.

According to Sam Korkees, Co-founder at EVSE, they can help 90% of Australian fleets without the need for expensive electrical upgrades.

The concept of load management is simple. There’s a limited amount of electricity available in every building. The total amount was calculated based on the intended use when it was constructed. For example, an industrial factory may have more than an office complex of a similar size. Regardless of the use, a problem arises when an EV charger is installed because the buildings normally operate close to capacity.

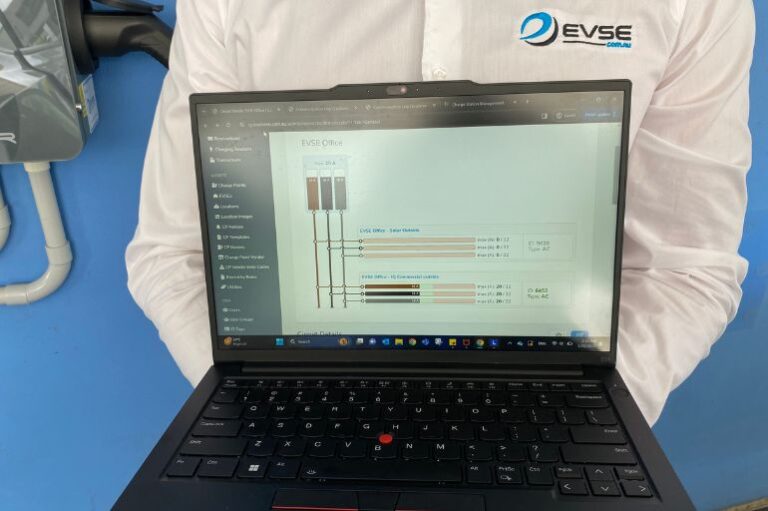

Load management software can control and prioritise how the electricity supply is being used. Obviously the main building and the business operations get priority. Then the software can allocate any spare capacity to the EV chargers. As demand changes during the day, the EV chargers can take more or less.

Using load management software, providers like EVSE can help fleet customers vary the charging patterns on the electric cars as they learn more about the usage patterns of the drivers.

The starting point is to allow the EV chargers a fixed amount (normally the excess capacity from the building) which is then split between multiple chargers as more vehicles are plugged-in. This is called static load management.

With dynamic load management the software varies the charge based on the programmed rules. This means the chargers could get access to more electricity from the building, or some chargers could be prioritised to receive more. You can even program the software to favour the boss’s car; or the sales rep with no access to home charging.

Scheduled charging is an advanced method of load management that explores the economics of an EV fleet transition. It can be used to let vehicles charge when electricity tariffs are at their lowest, or when free solar power is available. It’s being used by mature fleets that understand the daily needs of the fleet and their electricity purchasing agreements.

When writing an EV transition plan there are three options for charging the fleet:

- On premises charging (Office, warehouse or depot)

- Employee home charging

- Public charging network

In reality all three will play a role at some point. Most early adopters are back-to-base fleets so charging at the workplace will be the main method and that’s where load management will help you accelerate the transition to electric vehicles without the massive investment in electrical infrastructure.